On May 11, 1959, a nice spring day, our country school teacher, Mrs. Findrew Nelson, led the whole school on an all-day field trip – to Clarkson, Nebraska. All smirking aside, it turned out to be one of the most interesting and memorable field trips that I experienced in all my school days. We toured a variety of interesting businesses, and learned about the inner workings of places that we knew only as customers or store fronts. In the morning we toured the dairy on the east side of town and learned how milk was collected, processed, packaged, and distributed (milk was still delivered to the customers’ doorsteps in glass bottles in those days). At the Clarkson Hatchery and Farm Supply, we were told about commercial feeds and the business of chicken and egg production. At the offices of the Colfax County Press, we were greeted with the sights, sounds, and smells of the newspaper publishing business; at that time, they were still setting type with individual lead type letters, and we left that tour stop with a lead stamp of our name in the Press’ typefont. And sometime during that day, we drove up the hill on the west side of main street, walked over to a wooden garage/outbuilding, and were greeted by an old man who was arguably Clarkson’s most famous personage – Frank J. Richtig. Frank J. Richtig, a blacksmith turned car dealer turned knife maker, has the distinction of being the only person in Clarkson, and likely the only in Colfax County, to have been featured in Ripley’s Believe It or Not!

I remember very little of the tour of Richtig’s workshop; it didn’t look much different from the workshops in most farmer’s machine sheds. It was dark inside, the walls and shelves were covered with hammers, knives, saws, and other tools, and on the floor were piles of scrap metal. He probably told us about the process of forging steel, showed us how to heat it red hot in order to pound it into the desired shape. But what really caught our attention was when he performed his well-known feat – he held up one of his knives and, with a hammer, pounded the blade through a three-quarter-inch-thick strap of steel and cut it in two. He did this several times, then held up a piece of paper and sliced it like a razor with the knife that had just cut through steel. It seemed so impossible to us that we wondered whether it was some kind of trick. But it was no trick. Richtig was able to do this because many years earlier he had discovered a process for hardening steel that was truly revolutionary. A secret process that he took with him to his grave.

Frank J. Richtig was born on December 28, 1887. In 1906 he apprenticed to a blacksmith in Clarkson, Frank Koci. By 1908 he had gone into partnership with Joseph Walla (their first blacksmith shop was located on the site of the Dr. O’Neal’s medical office). Between 1910 and 1920, in addition to smithing, Richtig sold cars in partnership with V.L. Prazak; over the years they sold Dodge and Dort cars, and something called a Guaranty truck (“any make of car can be converted into a durable and guaranteed truck”).

Notice from the sign the original spelling of his name – Rychtig. This spelling was used around Clarkson into the 1920s.

During this time, Richtig began experimenting with the process of tempering steel, with the goal of creating knives that were so hard that they would rarely need sharpening. By the mid-1920s or early 1930s (the exact date is uncertain), he perfected the tempering process that resulted in knife blades so strong that they could “cut horse shoes into small pieces, as well as three-fourths inch crowbars, automobile axles, and even industrial steel locks, and yet undulled and without sharpening, still have blade enough left to cut paper into bits.” By 1935, production of the marvelous knives was in full swing. The October 17, 1935 issue of the Colfax County Press reported:

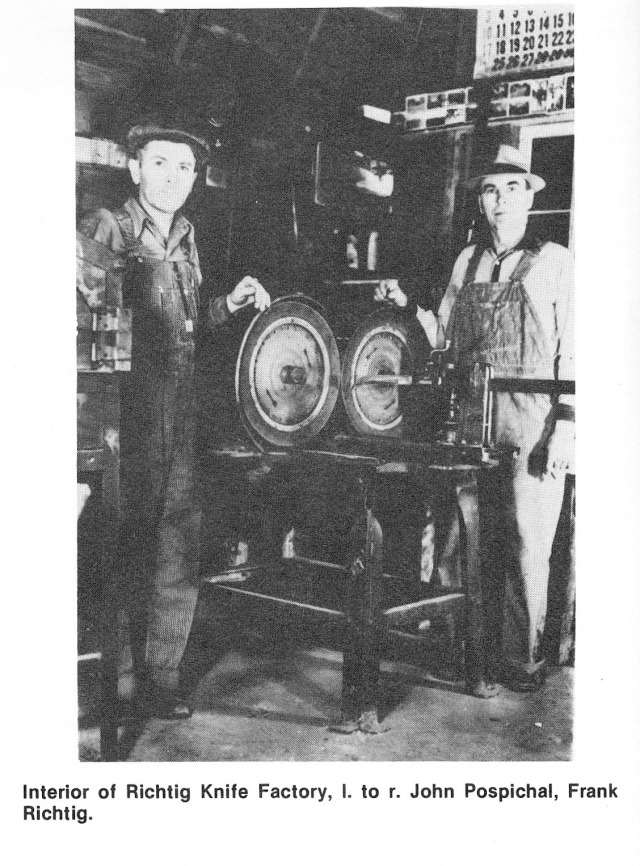

Richtig made a variety of kitchen and butcher knives, often with poured aluminum handles. He made a circular display rack to show the different types of knives he had for sale, and with a two-wheel trailer he took his products to county and state fairs, giving demonstrations of the unbelievable strength of his knife blades.

The Colfax County Press of September 16, 1937 reported that “Frank J. Richtig, Clarkson blacksmith, was on the fairground today demonstrating his steel knives that cut through three quarter inch cold steel. After driving a knife through a crow bar, chisel, or steel bit, Richtig will shave a piece of paper with its fine edge. Clarkson is a Bohemian district, and although Richtig is American born, he speaks with a heavy accent. But making knives, not talking, is his business in life, and he lets his traveling companion Julius Wacha, retired Clarkson general store owner, do part of the explaining. For 29 years he has made knives during odd moments when other blacksmithing was not pressing. Through long practice he developed his own technique for tempering the steel. Many offers have come from large steel concerns for him to join their companies and teach his secret to their men. But in Clarkson he has his home, his family, and there he prefers to stay. Through Colfax, Stanton, and Cuming counties Richtig is famous for sharpening plow shares, Wacha says, and in his time there he has worked on at least 60,000. Two years ago Richtig decided to extend the sales of his knives, so he began making the fairs, giving demonstrations. Most of the actual sales are mail order. The knives are not hard, Wacha explained. But they are so tempered that they will hold a razor edge.” (In addition to Julius Wacha, others who toured with Richtig to help with his demonstrations included W.J. Moore, Frank J. Svik, A.C. Fajman, George Bohacek, James Stransky, Marvin Teply, and Louis Faltys.)

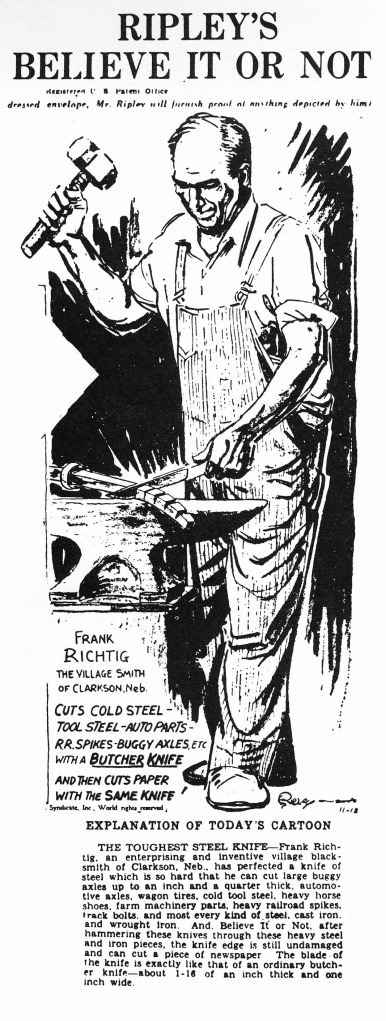

After he used one of his knives to cut off the hardened lock on a jail cell in Cedar Bluffs, Richtig drew the attention of the editors of Ripley’s Believe It or Not, who asked for information. A Clarkson artist, William Powolny, drew up a sketch and provided the text for the Ripley column, which appeared on November 18, 1936.

After the Ripley story, he became something of a celebrity, and the orders for his knives came pouring in. He received thank you letters for gift knives sent to such notables as President Franklin Delano Roosevelt, Gen. Dwight D. Eisenhower, Adm. Chester W. Nimitz, Gen. George Patton, and Gen. Douglas MacArthur. During World War II, he received many requests for combat knives. Unlike the kitchen knives, which featured smooth aluminum handles, the handles of the combat knives were comprised of discs of leather and red and yellow plastic. Richtig often gave free combat knives to local men who left for the service. Good examples of these combat knives easily bring over $4,000 among collectors.

Although Frank Richtig made large numbers of knives between 1935 and 1950 and continued to give demonstrations and make knives until his death, he always kept the tempering process that he had discovered a closely guarded secret. It is known that he did not forge his blades (like the legendary Japanese Samurai swords and the Arabs’ Damascus steel swords); rather, the hardness was achieved by grinding the blades from stock and relying on the subsequent heat treatment to develop their unique properties. Frank J. Richtig died on January 1, 1977, having told no one how to recreate the process. “A man is entitled to some secrets,” he once said, “and that’s mine.”

But scientific curiosity is not to be denied. Twenty three years after Frank Richtig’s death, Dale Novak, a relative of Frank’s and an excellent knife maker himself, sent two of Richtig’s knives to Lawrence Livermore National Laboratory in California. Two metallurgists studied the samples and published the results of their analyses (Jeffrey Wadsworth and Donald Lesuer. 2000. The knives of Frank J. Richtig as featured in Ripley’s Believe It or Not. Materials Characterization: An International Journal on Materials Structure and Behavior. Volume 45, pages 315-326). The scientists subjected the Richtig blades to a battery of tests: measurements of hardness, chemical composition, tensile stress, and high magnification analyses of the steel’s microstructure. And for good measure, they used one of the Richtig knives to hammer through a 6-mm-diameter steel bar without damage to the blade (a test that caused a contemporary high-carbon steel kitchen knife to chip).

So, for those of you who have waited all your lives to learn the secret of the unbelievable hardness and enduring sharpness of Frank Richtig’s knives, here are Wadsworth and Lesuer’s conclusions: “Our best estimate of the Richtig secret recipe is as follows:

1. AISI 1090 or 1095 steel was used.

2. The steel was austenitized at a temperature just slightly above (e.g., 30 degrees C) the A1 temperature.

3. The steel was austempered at 300-400 degrees C.”

Or, in layman’s terms, Wadsworth and Lesuer deduced that the knives were made with ordinary carbon (1%) steel that was heated to nearly 1400 degrees F, rapidly cooled (in a second or less) to around 600 degrees F, and then held at that temperature for “tens of seconds.” Outside of the laboratory, they noted that such rapid cooling could be accomplished by quenching the thin blades into an isothermal salt or molten lead bath held at the appropriate temperature.

The scientists observed that “the use of an austempering process by Richtig is quite remarkable, since the process is generally recognized to have been introduced by Bain and Davenport in the 1930s. Since the Richtig knives, made with the secret heat-treating recipe, were famous by the 1930s, it is possible that Richtig discovered the austempering process before the two well-known metallurgists were generally recognized for discovering the process.”

Not a carnival trick, Frank Richtig’s knives were the real deal. And it appears that our Village Smithy was the first to discover the austempering process that made them so hard – before the later development and promotion of the process by professional metallurgists.

Metal pipes and rebar have never been safe since…

Most interesting. I think Clarkson should hire you as their historian. Thanks for sharing this info with us. I am not certain that I have ever seen one of his knives. Quite an accomplishment for someone without a lot of resources. Great! Thanks, Bernie

I have 11 knives that Frank made for me. I loved going to his shop and listening to him talk. I wish I had saved more of them!

Tony, while I didn’t know you had 11 of them, I have no trouble remembering the times we went to Frank’s shop. At one time, I had 3 of them but gave one to my brother. The other two are remarkable. One is the aluminum poured handle kitchen knife that i use for nearly everything everyday, and I can’t recall every sharpening it over the 30+ years of ownership. The other one is a fabulous hunting knife with the leather handle that he custom made for me. He was so old at the time that when he tried to stamp the knife with his trademark, he missed with the hammer. The result is somewhat of a “half trademark”. For a long time, I was disappointed that I didn’t have the full trademark but now that I’ve read this it makes me think I’ve got something special. Thanks for sharing this with me. Bob Keefer. Raleigh, NC. rkeefer3@nc.rr.com

Hi Glen,

Great job on the Richtig Knives, I had totally forgotten about that, but remember the Ripley’s Believe it or Not in the Colfax County Press.

Good stuff! Tom

Tom Cech

Fort Collins, Colorado

cech52@gmail.com

Hey, Glen –

I do remember hearing about the Richtig knives. Interesting research on the makeup of the knives and the findings by the two scientists. Just for giggles, I Googled Richtig knives and all sorts of information appeared. I believe I’m going to read some more. Thanks for the information.

Connie – A lot of people around town had his knives, especially the kitchen knives. They don’t wear out, so they get passed around. I wish I had a few of his hunting and combat knives!

I can add a little to the Richtig story. As a young boy for a number of years during world

war two he was in need of aluminum to make his knives. My dad had quite a few pistons from doing overhaul jobs on cars and tractors and when my Red Ryder wagon got full I would take them to Frank. Many times when I took them there he was tempering blades. In the process he took them off the forge and dipped the blade in a solution in a bucket, I don’t know what the solution was or how long he kept them in it, but after they cooled he would hit the blade on an anvil with one hand and with other he would hit a tuning fork. If the tone was the same the blade went into the good blade bucket, if not it went to the forge later. I don’t know how many trips I made but a lot of them. When Jan and I got married 60 years ago we went to buy knives for keeping house and still have some. He said to me, Jimmie I thought this carving knife set was going to be for my doctor, Doctor Kolouch. When I’m done with them they will be your wedding gift. I don’t know if he lived long enough to make another set or not. Jan was nervous about having them in our china cabinet with four children and their friends being alone in the various places we lived so about 25 to 30 years ago at one of our garage sales somebody offered me $500.00 for them. Wish I still had them but you know the story happy wife, happy life.

The Frank Richtig knives are a popular item world wide. I have been buying them on eBay for some years now. Each year they seem to go up in value; any worn butcher knife brings at least a hundred dollars. A few years ago in West Point I went to an auction featuring Frank’s knives; one of the most interesting items I found there was a large photograph of Admiral Nimitz on a battleship with a crew of sailors (don’t remember the name of the battleship) on the back side was a personal letter from Admiral Nimitz thanking Frank for all the knives he had made for the military along with a few of the knives. I remember bidding over $200 and losing out to a fella from Clarkson who was a collector. (big mistake on my part). Robert

I recently purchased one of his knives and reading this was extremely interesting & helpful. Will be watching for others now. Thanks, Lee

When someone writes an paragraph he/she maintains the

image of a user in his/her brain that how a user can understand it.

Therefore that’s why this piece of writing is perfect.

Thanks!

Thank you!

Excellent write up, there’s not much I could possibly add to it, other than one little addition. I was the one who sent the Richtig blades to the Lawrence Livermore national laboratory for testing. Even though the blades would be destroyed in the process, and could never be replaced, I felt that it would be worth it. I have the a copy of their original pre-published report. Again great write up. Sincerely Dale L. Novak.

Thanks, Dale. I wondered how two metallurgists in California got hold of those blades. You sent those knives to the right place. The lead author of the Richtig Report, Jeff Wadsworth, went on to become the Director of Oak Ridge National Laboratory, a collection of 5,000 research scientists and engineers. He was my boss for a few years.

Glenn

Glenn, the guys told me that they liked a really good mystery, and I figured this was a really good one! They contacted me after seeing my CBS Sunday Morning spot.

It’s a great story, for sure. I was glad that I got to meet Frank – he was your uncle, right? Has the CBS story aired already?

Glenn, Frank’s wife Mary, was my paternal grandmother’s ( Adella Uher Novak’s) sister. My dad’s aunt and uncle. The CBS spot ran in 1996 I think. It was one of Roger Welsch’s postcards from Nebraska.

Dale, are you still making knives??

Michael A Losicco,

I was reading this article and comments and came across your message from 6/23/16 to Dale Novak asking if he still made knives. Not sure why he didn’t reply at that time. But to answer your question: Yes, Dale was still making knives in 2016 but not as many as he had in the past because he was just too busy with work and family.

Unfortunately, Dale passed away this past July at the age of 64. I grew up in Clarkson and Dale was one of my best friends. I think Glenn should do a story on Dale, Clarkson’s modern day knifemaker!

If you have one of Dale’s knives, it is a treasure. I have a letter opener that he made for me in 1995. He put his name, Clarkson, Nebraska and the date he made the knife on each one in addition to the number of the knife. Mine is labeled #69, so it is one of the first ones he made. I know a knife collector in Clarkson who owns several of Frank Richtig’s knives and Dale’s knives. He feels that Dale’s knives are better than Richtig’s. Of course, Richtig knives were more of a factory process since he produced thousands of them. Dale’s knives were made with more time involved and quality craftsmanship. Dale was creative and a skilled craftsman. He could make almost anything that he set his mind to.

Another interesting story related to Frank Richtig: Dale told me that when he was in grade school he visited his great-uncle Frank often with his family and became interested in Frank’s knifemaking. When Dale was in high school in the early 70’s and not long before Frank died, he asked him if he would teach him to make knives and carry on the tradition. Frank told him no, he wasn’t going to give anyone his secrets to knifemaking. Dale was disappointed, but said heck I’ll just make my own then! And he did! Better than Richtig’s!

Dan Nosal

I am a custom knife maker and have 2 of his knives in my collection and count them among my most prized pieces. One is the 5 inch or so aluminum kitchen knife and the other is a leather handled fighter from WW2 that a friend of mine gave me that he had found in his basement. Knowing I liked knives he gave it to me, neither of us knew anything about it until I found some info from a friend on a forum. I told him and offered it back but he was generous and insisted that I keep it , Definitely a blade Ill keep for the rest of my life. They are superb blades.

The combat knife is a real prize- you’re lucky to have it. What I like about them is the back story – that Frank gave them away to the servicemen who were going off to war.

My grandmother had a knife that looked exactly like that, but it needed regular sharpening. Must have been a knockoff.

After Joe and I were married in 1962, my dear neighbor, Calista Jindra, brought two of Frank’s knives to my mother telling her that I “must” have them.. I was gone from Clarkson long enough to miss out on a lot of Frank’s skills. So I know I have two of his knives today and yet I cannot identify which are Frank’s knives. After reading all of this info, I will try my hardest to identify Frank’s knives as I know I own “the greatest handmade knives made.” I remember Frank, more than his knives. This man never realized his worth and skill. God bless him.

I have three of Mr. Richtig’s kitchen knives and a custom hunting knife he made for me in 1965. I still use the hunting knife and the aluminum handled knives are in a special drawer in the kitchen.

I picked up the knives and met Mr Richtig . A very nice man , and very gifted with steel. Larry Kmoch

I am currently working on a farm in winslow nebraska. while digging around an old barn I found a wonderful looking blade in he dirt. not knowing what was in my hand i took it to the brush wheel on the grinder to clean it up. what i found it an awesome looking blade Mr. Richtig made. trademark stamped and all. i am a lucky man as ive read this writeup and others and discovered that this man is legendary and I am blessed. Thanks for this write up. any response would be great.

Marcus Goodman

socco510@gmail.com. ThNKS.

Lucky you, Marcus! Frank Richtig’s knives ended up all over the world, from kitchen drawers to battlefields to the Oval Office. Does your find look like any of the knives in the article? Glad you enjoyed the post.

Great story and info on a great knife maker. I am privileged to own 5 of his knives. The first one I picked up at a gun show in Unadilla NY. I have been collecting knives for a few years at the time but mostly pocket knives but had read Levine’s book on knives and always wished I would find a knife buy what he calls the ” Pioneers of modern hand made knives”. So as I was looking at a group of straight knives a gentleman had on his table, about 50, when I spotted the leather handled hunter. I was smitten right there with how the knife felt in my hand. If you have never handled one go to a knife show and see if there are any there and ask to hold one. Like I said I am lucky to own 5. A fighter, and dagger, a mini and a mid sized, all have leather handles and the lanyard loop. The last one is ivory handled with aluminum hardware that is a mini.

Vitame Vas. Czech Days take place in Clarkson in June, this year (2015) Friday 26, Saturday 27, Sunday 28. Come enjoy his hometown celebration, take in good food, entertainment, the Museum, all sorts to see, hear, taste and partake. My father came from Clarkson, many a time we would go up the hill and see Frank in his shop with projects under way. In addition to his knives, one invention stood out to this kid. He made a holder for fishing rods, which when a fish would hook and pull, the action would be activated to jerk the rod to set the hook and fire off a cap to alert the snoozing fisherman. Not sure if it was his own idea, but sure caught our attention, and the fish. The whole family enjoyed his friendship and super knives.

Yes, I remember that fishing rod holder as well. He told us it was his invention. And it was a darn good one!

I grew up with these knives, the only paring knife I ever remember using. Wish I had one in my possession.

I am very happy and proud to say this man and his wife were my great uncle and aunt. I remember when my daddy took me there and uncle Frank showed me the art of his knife making. He was and is a great man in my book.

Some great names from my youth. I bought a hunting knife from Frank in 1959 and kept it until it was lost on a hunting trip in approximately 1999. Was a prized possession.

Norbert H. Kmoch

Excellent article! I wanted it to just keep on going! I still can’t forge a flat blade to save my life. Some of my husbands blades are beautiful to look at and to watch being made….but nothing like these blades, of course. As the wife of a blacksmith I love stumbling upon really great reading like this.

Thank you!

Wow, very interesting reading and historical article.

try this on for size. get a horizontal quench tank. fill it with distilled or rainwater. add ice and rock salt . stir until very well mixed continuing to add rock salt until you get a somewhat medium thick slurry. gently add transmission fluid until it covers the top of the water lay the blade in as if cutting when quenching. after the quench then heat to 1050 degrees and put the blade into vermiculite until cool. this is a quench some used for doing plowshares. it work’s very well. i got this off a guy i met way back i was talking to on a city bench . try it you might like it. seldom have i ever told anyone about this quench.

I found what appears to be a kitchen model knife in a box of tools at an estate auction in Malcolm, NE. I only bought it because it was made in Nebraska, and I grew up and live in NE. Never heard of the knife before, but it appears I am lucky to own one. It is well used, but I can’t wait to clean it up and sharpen it. We’ll see if it becomes one of my favorite knives.

Great article on a great maker but it should be noted that richtigs knives weren’t exceptionally hard, in fact they are actually considered soft compared to what is commonly believed to be a “good” knife. Richtigs were about 50-55hrc hardness, while most “quality” knives are closer to 60hrc if my memory is accurate.

I have 2 of Frank Richtig’s kitchen knives that have never been used. One is a large Kitchen Knife with a 6 inch blade, and the other is a smaller Kitchen knife with a 3 1/2 inch blade. They both have the “F.J.R. Clarkson Neb.” stamped on the left side of the handle. They (along with one of the leather handled hunting knives) were a gift from my step-grandfather as a wedding present in 1963. He lived in Lincoln, NE and was a supplier to Frank – he supplied him with the leather which was used to create the handles of the hunting/combat knives. The hunting knife I sold at a Gun & Knife show in Columbia, SC, in December 2004, for $600.

NOTE: Both knife blades are still sharp and shiny after 54 years in my possession.

I remember holding one with brass knuckles he made for my Uncle Ed Svoboda when he was a Marine and I was about 9. Later he gave me a Jap hand grenade, which I still have but not that knife – darn it..

Another great article! I agree with Bernice Cada….you should be hired as Clarkson’s historian!

Thanks! I wonder what the job pays? ha.

Very, very interesting! As a Blacksmith and knife forger I have been long fascinated with the mystery of hardening and tempering steel. I have been able to make very serviceable power hammer dies of mild steel using a similar process, from a “sunrise heat” quenched in ice water brine, mild steel becomes file hard, and super tough. I have seen very few Richtig knives and never knew what a treasure of metallurgical knowledge they held. I have been doing research on the process of “edge packing” and have some micro-photos that show remarkable results, and edge holding tests that further prove the value of this process.

Mr. Richtig gifted us a set of three knives when Bud and I got married in 1956.

He also made an army knife for Bud and our son Bruce.

We go to enough garage Sales and Auctions to realize their value and the collectibility.

When I taught at the Walla District I too, took students to see the work shop.

Wonderful contribution to our Home town.

Thank you,

Betty Tomasek Dasenbrock

Thanks, Betty! Best wishes,

Glenn

I was very fortunate to grow up when both Mr. Richtig and Mr. Novak were alive. My mother Irene Malena Bishop received a butcher and paring knife upon her marriage in 1945. Later in the fifties my grandfather took me to Franks house up the hill to witness his workmanship. Grandpa Malena had Frank make him a hunting knife that was given to my father and later in the nineteen nineties Mr. Novak made me an identical hunting knife. I greatly treasure them, beautiful pieces of Colfax county history…….. Ed Bishop

Yep, last name Brabec – if you know Clarkson the name should “ring a bell”. Fortunate enough to have been given 2 WWII fighters, 1 about 9 inch blade, the other 6, both in their tooled Cornish sheaths. Belonged to my Grandfather and Great Uncle – their initials were stamped into the pommels. As Clarkson residents serving in WWII, Frank gave them to them before going overseas. My Dad didn’t know they were anything exceptional growing up – said he used to throw them at trees – glad they’re tough as they held up well – no bends and still have blade tips! Been offered PLENTY for them – but some things you just have to hold onto – only a fool says never for sale, but I hope to never be in THAT position in life.

Great story about F. Richtig. I myself had a knife book which I call a “wish book”

and was amazed about his knives. Being in upstate New York I figured I would

never run across anything like that, being there were too many knife collectors

at the gun shows. I started to go to a lot of local auctions and I lucked out! There

was this auction in Schenectady, NY and it stated it had some military items. I

found where it was in a old bldg. where there was very little lighting, I parked and

went in and looked around, I found the military items and carefully looked at all

the items. A lot of uniforms, web gear, and several knives. I looked at each very

carefully and there it was, leather stacked, brass pommel, brass crossguard, double

edged blade with well made scabbard with the Dr.s name on it. I looked all over

but could not find any FJR markings but I knew it was his with the loop on top!

The auction started and I waited until they started putting up the military knives,

I bought a couple others, but I wanted that special one. They put it up and I thought

I was going to get it for $45.00 but this other fellow that I know started bidding on

it. Well, finally I got the knife for $200.00. I went over to the guy and asked him

why he was bidding on it and he said, Because you were bidding on it! I asked

him if he knew what kind of knife it was and he said, just a well made G.I. combat

knife! I’ve had that knife for over thirty years now and cherish it greatly. I found

the family that put all the items for sale in the auction. I asked about the G.I.

I was told that he was a doctor in WW2 and while home on leave went to a fair

in Iowa and bought his favorite knife for $50 from a guy who could cut horseshoes

with his knives. After he passed away they didn’t think anyone wanted this stuff

and auctioned it all off. The rest is history!

ric

Great story, Jim. Your persistence paid off, and I’d say you still got it for a good price! There are a lot of collectors out there who wish they had one of Richtig’s knives.

Could the knives have been brought down by quenching in hit aluminum? I think it melts down at around 650°c or 670°c. He was already working with molten aluminum to make handles .

Great article.

Yes, Richtig made a lot of aluminum knife handles. I don’t know if he made them from molten Al or just shaped blanks. I doubt that the blades were quenched in molten Al because it solidifies below 660 degrees C, which is still considerably higher than the supposed austempering temperature of 300-400 degrees C.

hello friends of clarkson, is this knife made by frank richtig? it is unmarked, thank you for any help